-

-

Innovative

Center

Vertical Integration Model

Following Cacao-Trace program, Puratos Grand-Place Vietnam has built the vertical integration model. We work closely with cocoa farmers within their communities to share our expertise on good farming practices that promote productivity, environmental protection and ensure the highest quality of the cocoa. The post-harvest centers are opened at the cocoa plantation areas to purchase the cocoa bean, take care of the fermentation process,

and sun-drying under our expertise to enhance the origin cocoa flavor. The cocoa mass production step is also designed at one site to produce right after the dried beans are ready. With this model, we have the fully controlled & closed process from bean collection, fermentation, drying, cocoa mass making, this helps to create the best quality.

Farming

Farming  Fermentation

Fermentation  Sun Drying

Sun Drying  Roasting

Roasting  Cocoa mass making

Cocoa mass making  Chocolate making

Chocolate making  Chocolate bar

Chocolate bar Innovative Liquor Line

As with wine-making, fermentation is an essential stage in developing the flavor potential of each cocoa bean. Puratos Grand-Place Vietnam takes prides in being the first and the only enterprise in the world to have a special centre for post-harvest processing where our expert team ferment cacao beans by its secret methods.

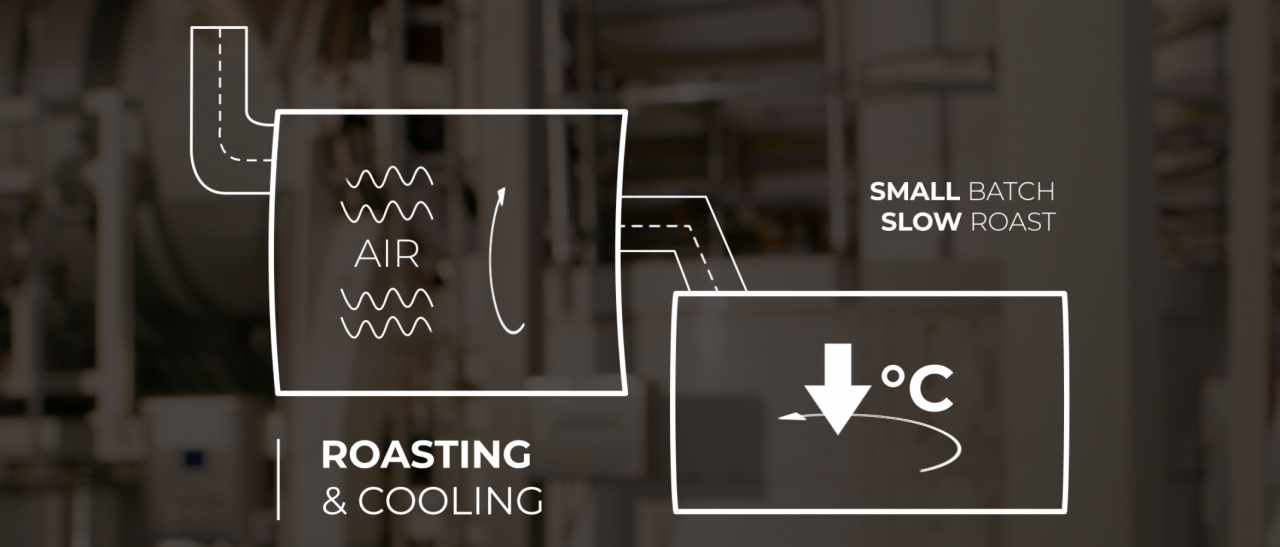

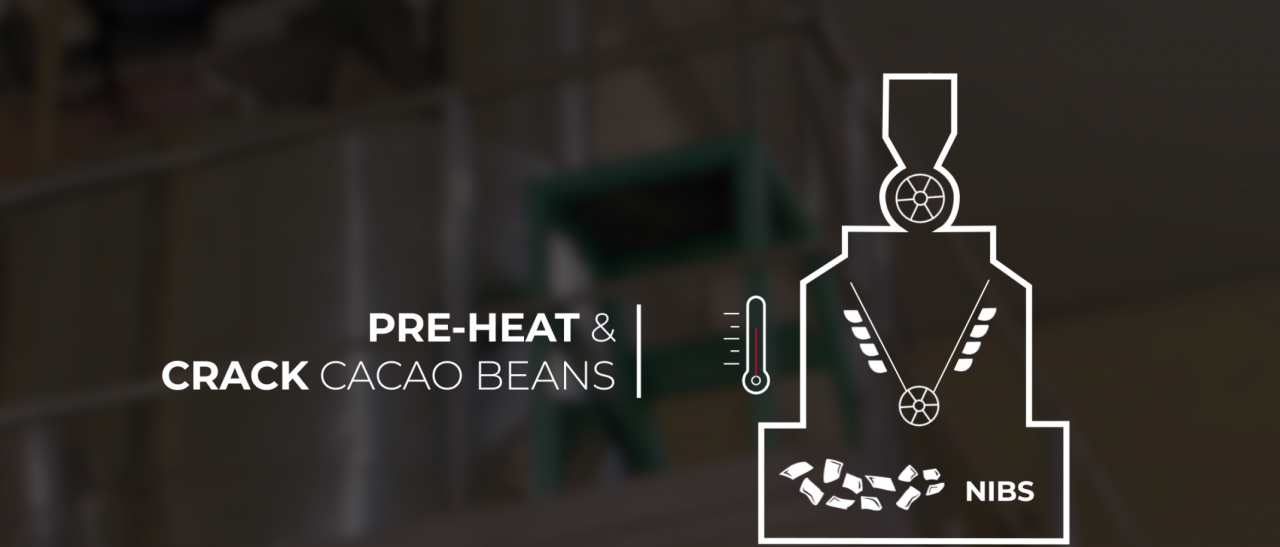

And thanks to unique roasting facilities, we are able to toll-roast our fermented beans in small batches. This gives us the advantage in preserving all the original flavors by flexibly adapting roasting times and temperatures to the characteristics of the beans. Low-heat and slow roasting is then applied to fully develop the cocoa beans’ uniquely natural taste.

CSR

Starting with the Cacao-Trace model that elevates Vietnam’s cocoa beans, PGPV continually pursues sustainable business development which is a sustainable, respectful, and balance commitment to creating a positive impact on society. For our customers, to provide a superior chocolate taste we are focusing on creating value through a standard fermentation process, designing the tailor-made cocoa mass production in small-batches, slow roast, and low heat.

With the farmers – the most important players in the whole cocoa supply chain, we are sharing value back with them through the chocolate bonus program. Besides, we achieved the carbon-neutral certificate for the whole company in 2019 and implement the agroforestry project with cocoa planning, both are two critical projects that we have been deploying for years to ensure our business development in harmony with nature, people, and the planet.

Certification

Our modern and efficient facilities are certified with many certifications that ensure we meet the highest quality assurance standards and appeal to businesses that wish to reach a variety of markets.

We are also proud to pass various third-party audits every year without any major remarks. The continuous auditing system ensures we are performing to the best of the industry standards.